Project Background In 2023, a mid-sized glass fabricator in Buenos Aires sought to upgrade its workshop to expand decorative glass production and meet growing client demand for customized patterns and fast delivery. Client Requirements A Glass Laser ...

Project Background

In 2023, a mid-sized glass fabricator in Buenos Aires sought to upgrade its workshop to expand decorative glass production and meet growing client demand for customized patterns and fast delivery.

Client Requirements

A Glass Laser Sandblasting Machine capable of complex surface designs

A CNC Glass Cutting Plotter for high-precision straight and shape cuts

Stable equipment for daily production of over 1,000 m²

Full documentation, English training manuals, and remote support

Our Solution

We delivered two core machines from our advanced equipment line:

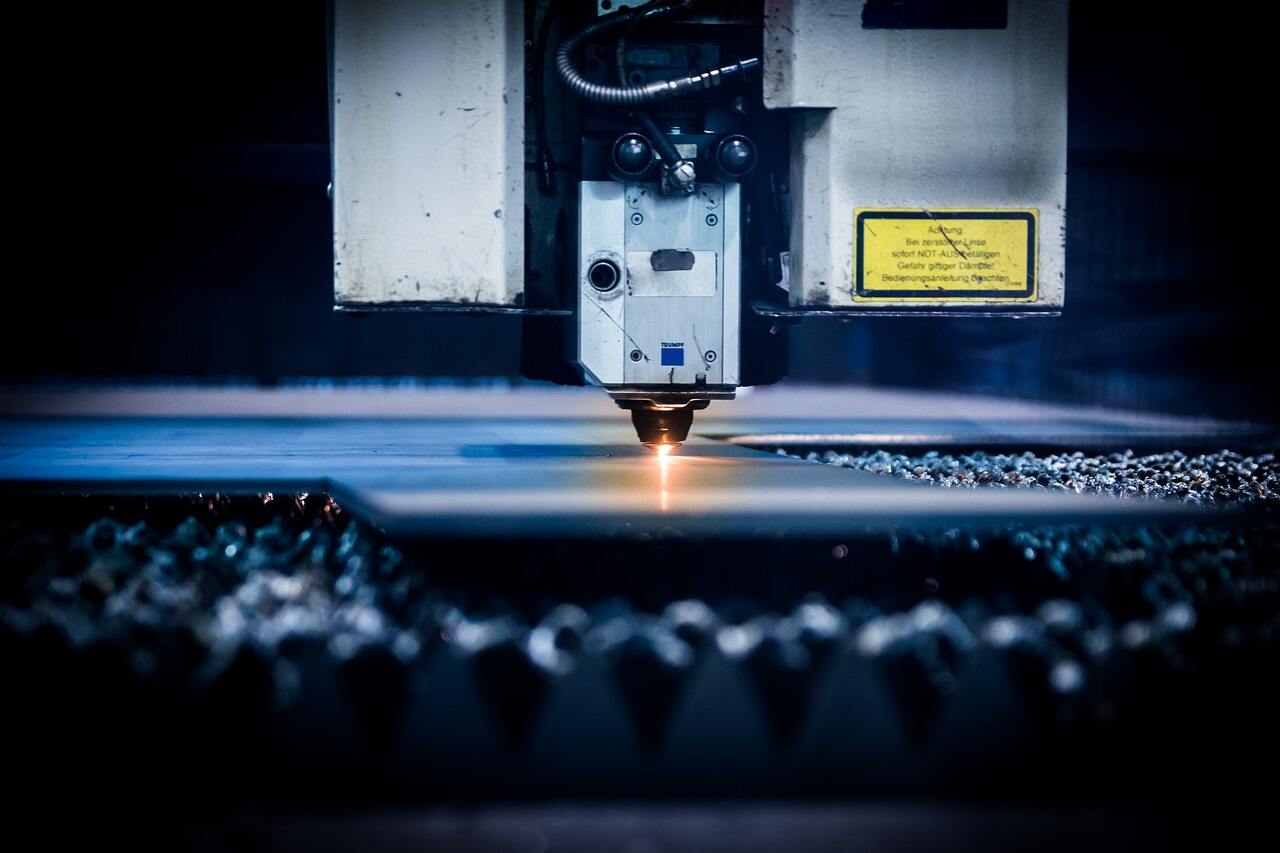

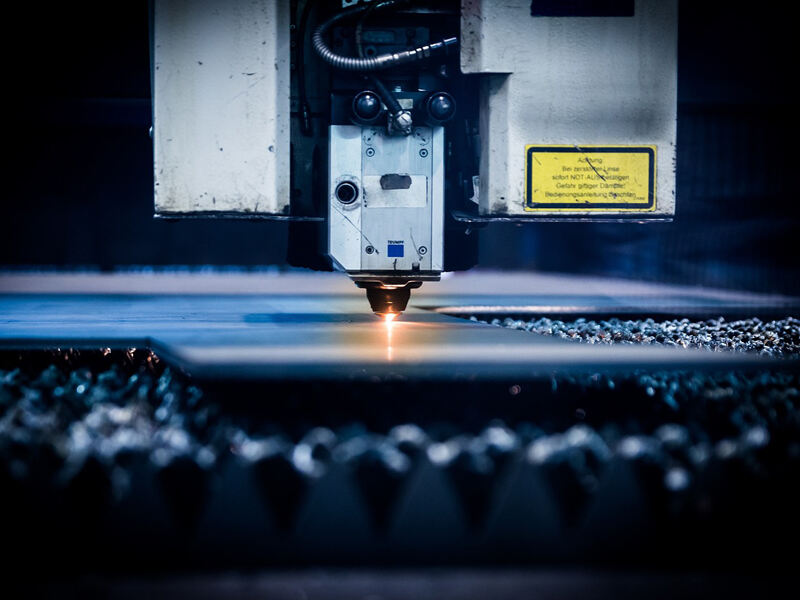

Laser Sandblasting Machine – supports grayscale engraving, logos, and full-surface frosting

Vertical CNC Cutting Plotter – accurate to ±0.2 mm, with touch screen and self-calibration mode

To ensure a smooth onboarding:

A video-based training program was included

Our engineer provided virtual commissioning support

Spare parts and software updates were included for the first year

Project Outcome

After installation, the factory’s output capacity increased by over 40%, with reduced breakage rates and a broader portfolio of glass products. Their clients responded positively to the fine detail and clarity of laser designs. The factory owner described the machines as “a true leap in productivity.”